During various preparatory and repair work related to the processing of metal surfaces, it is necessary to carry out stripping and grinding of all sorts of metal surfaces.

In addition to working with metal surfaces, grinding circles Allow to work with other materials, such as:

- ceramics;

- rocks;

- glass;

- leather;

- rubber;

- plastic and other materials.

Navigation

Catalog of types of grinding circles for Aliexpress

To date, a large number is presented. grinding circles, the main function of which is the removal of unwanted particles on the surface being processed. This surface can be made of any material, however, in this case, you should select grinding wheel Under the treated surface.

According to its work principle, grinding circles is the same canvas for a saw. Only in the case of grindingmaterials, the smallest teeth are located over the entire surface and the rudeness of processing depends on their magnitude.

Large teeth will remove a large number of unwanted particles from any surface, while it will remain deep furrows that will need to additionally process. The surface that is to be processed can be made of various materials, both rigid and fragile. With help grinding Circle and electric tools, grinding will pass high quality and quickly.

In the event that there is a slightly melting material, such as plastic, the use of high speeds will be undesirable. Large revs grinding Circlewill lead to a significant increase in the friction coefficient, which in turn significantly increases the temperature. An excessive increase in temperature can lead to the fact that the polished material will break.

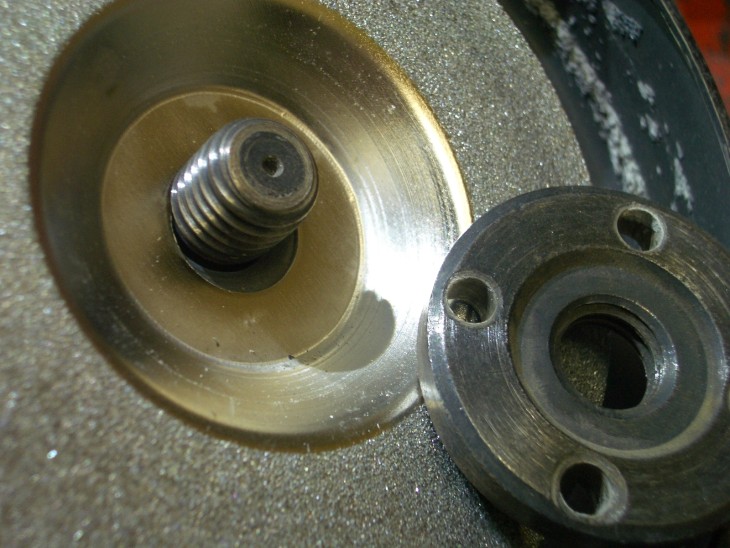

emery wheel

A large number of species emery Circles They may differ in the size of the grain, as well as by the material of the base to which they are attached.

Emery Circles can be both paper based and tissues. It is he who this material will depend on their durability. The paper base is less durable, it is faster thantening, and the teeth are much faster flying out, which leads to a more frequent replacement.

Emery wheel - This is a flexible material with an abrasive coating, which is fixed on special nozzles and connects to an electric drill, which allows you to work on large revs, thereby cope with the tasks set as much as possible.

Grinding circles They differ in color that symbolizes the size of the teeth of the abrasive material, with which the processing of various surfaces occurs. Grinding circles Can use to remove old paint and other straight-color materials from any surface, as well as their subsequent preparation before painting. Circles for grinding Adapted to work with highly involuntary electrical instruments.

Such abrasive circlesvery often used in the repair sector, when it becomes necessary to remove rust from old surfaces and prepare it for subsequent operation. At the same time are similar circlesthere may be different sizes of abrasive coating grains, which will allow you to use them for various purposes.

circle for sharpening

Circle on sharpened - This is a material made on the basis of abrasive materials. Such circleit is intended for installation on high-speed engines, with which the sharpening of various parts and parts is made.

The greatest popularity grinding wheel Used as a sharplification of certain items, including drills, nails and needles.

If necessary, you can pick up circleMade from high-strength material that can be processed and sharpened even the winner tips of the drill. As it is known that such material is to win, is used to drill high-strength concrete and granite.

Circles on sharpened Frequently installed on special sharpening machines, which in turn are used to sharpen various cutting items. With the help of such circlesyou can make sharpening knives, scissors. During frequent operation, gradual erasure occurs circle. Grains can be overwhelmed, eager, or smoothed. With uneven erasure, the use of such circleit becomes uncomfortable.

The wear rate of this grinding Circle Directly depends on the quality of the material used, as well as from its production technology. In soft abrasive circles There is a self-setting of the tool, whereas in solid, all parts are simply smoothed and stupid. Due to this, the further sharpening speed becomes much slower and the cutting ability is reduced.

In this case, it is necessary to make circlewith the help of a special tool, which is based on a diamond spraying.

circle on Velcro

In the event that the work is not at ultra-high revolutions, and the polished material will not require additional effort, you can talk about the possibility of applying Circles on Velcro.

This is a self-fading element of an electric tool that is tightly cling to a special nozzle having a ripple adhesive part.

As ordinary grinding circlesThis species may have different hardness. The hardness coefficient is calculated as the ability to hold grain on a special basis, when exposed to various external forces.

Using circlesfor materials of various hardness, you can find the following regularity: solid grinding are used to sharpen soft metals. circlesSince their resistance is significantly higher. And in the case of working with carbide materials, the best option will be the use of soft circlesBecause during operation there is self-sharpening, due to the breaking of already smashed grains.

However, the main material with which you have to work using circles on Velcroeis a tree.

circle sharpening

Sharp circle It is an abrasive tool in the form of a circle, which is used on special electrical devices. Used sharp circle In order to sharpen the cutting tools, which in the process of their operation were subjected to various physical impacts.

Sharp circle It has in its composition abrasive materials, which during use may be tupped, or disappear.

The working material is important, since it is from him that the choice depends sharpening Circle. Today, the use of similar circlesit is quite wide, which leads to an increase in demand. To sharpen the fastened knife, or make another cutting tool sharper, the most quick option will be the use of such circles.

diamond circle

Diamond is one of the most durable materials on the planet. It is used not only as decorations, but also for various technical purposes. According to statistics, more than 70% of diamonds used in domestic purposes is used as a diamond powder. Similar diamond powder used in quality Circles, Nadfils, grinding bars and other different grinding tools.

In industry uses several types diamond Circles, the differences in which in the binding of their material. If used grinding diamond circle Based on a metal bundle, you can significantly increase durability. Such circleshave a higher heat resistance and a large margin of strength, which allows them to be used with more aggressive use. However, among many positive moments, there is one negative, which is rapid insolence circle. Hence, circleit is necessary to make it much more often for it, which makes it use not so comfortable.

If using circleon an organic basis, it will be better to apply it with the final sharpening of the tool. Such circlesit is practically not arranged, and their use is very practical. Use of such circlesis more economical, in the case of using it with cooling, because They do not like overheating. Large disadvantage of similar diamond Circles is their high wear.

At the time of buying diamond Circle, including in the catalog AliexpressIt is necessary to take into account one of its most important indicators - the amount of diamond layer by 1 mm3.

The main and most important property diamond Circle It is its strength and high degree of cutting. Often, it is with the help of diamond Circles Performs finishing and sharpening tool, especially carbide saws, all sorts of mills and winning drills.

In one word that acquired diamond circleYou get high-strength and high-quality grinding tool that will be able to work for a long time.

circle petal

Grinding petal circle It is intended for the end grinding, while it is the most economical and safe tool.

Radial location petals on a circle It gives the greatest effect and high performance in the final processing of metal products, stainless steel and aluminum.

When choosing grinding Circle It is worth noting the fact that petal circlesallow you to make a refined material better. Like circlesallow you to work with a large area of \u200b\u200bthe treated surface, while wear of the petals is minimal. Result The use of petal circles will be uniform treatment.

Also working using petal circleit will be less noisy, and the level of vibration is also insignificant. During long-term work, the petals are gradually erased, up to the foundation, which makes it possible to use them for a long time.

Customer Reviews Price-Quality

When choosing and ordering any product in the catalog Aliexpressyou should pay attention to a large number of reviews. Buyer's review is an important component, regardless of their positivity, or negativeness. Largely important both the quality of the goods and its price. A large number of shops and high competition for Aliexpress allows sellers to adjust prices so that the buyer ordered the goods from them.

L *** D M. I did not try to grind, but in appearance made qualitatively. When rotating, the beat did not feel. I hope to be useful.

M *** L L. The order came to Moscow very quickly, in 2 weeks, the track was tracked. Grinding nozzles of very good quality and inexpensive. Apply when repairing a car, to remove paint and rust in hard-to-reach places. As you flow, I will order yet. Seller Many thanks and success in business.

D *** N A.The goods have reached safely and preservation, the appearance of high-quality. But, the shed holder will be wondering, as a result of which great beating.

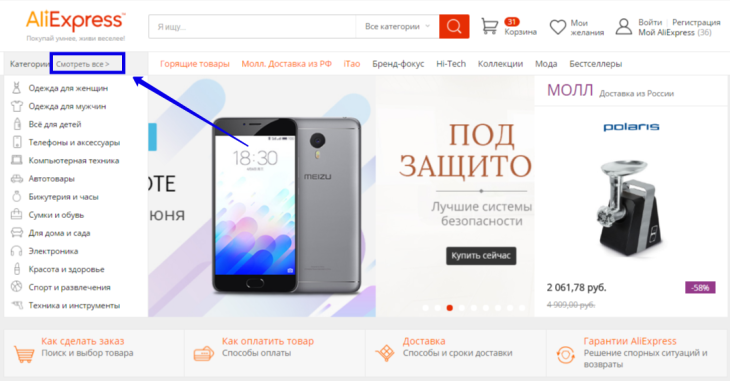

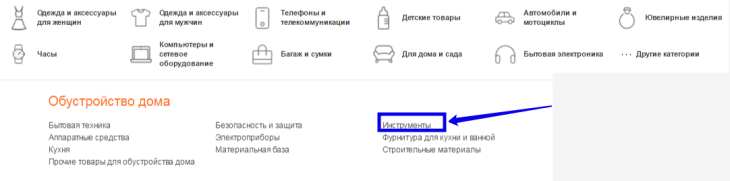

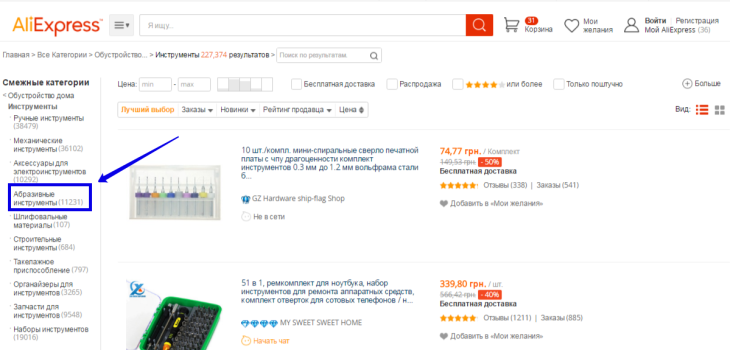

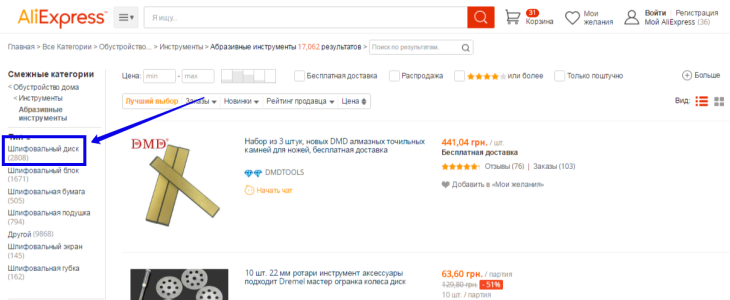

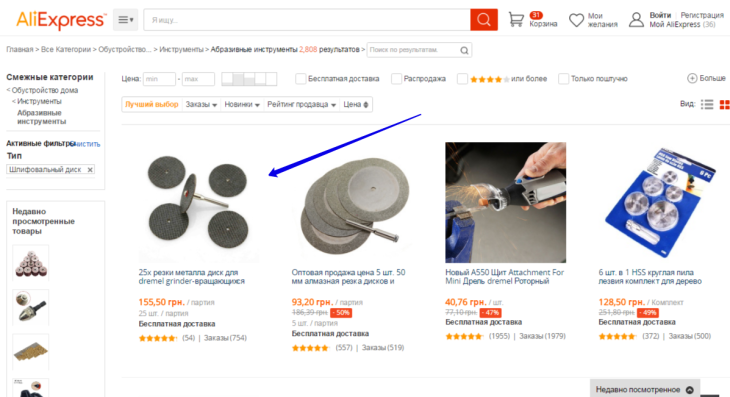

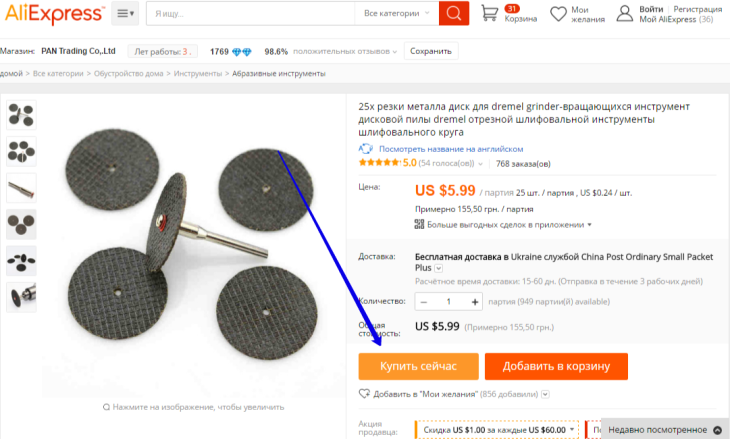

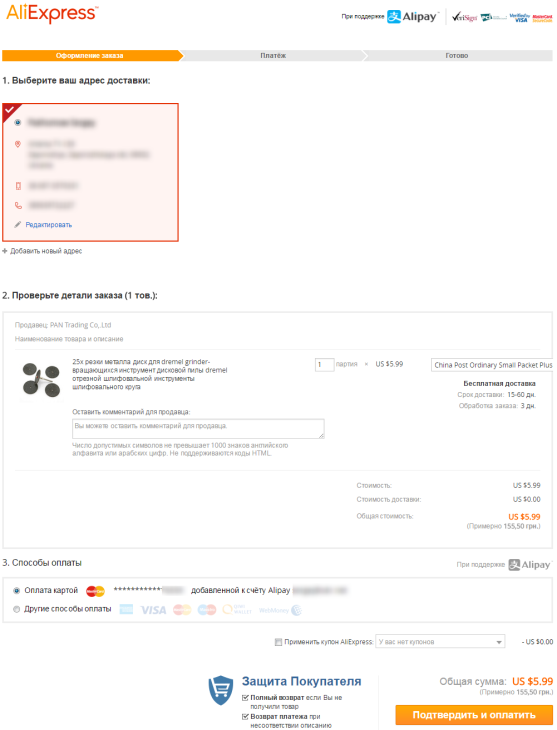

How to order grinding circles on Ali Spress

Related Materials

- Cacheback size for aliexpress? Cachek aliexpress divorce or not?

- Why can Aliexpress block an account? How to return the money If you blocked an account on Aliexpress?

- What is Chargesback on Aliexpress? How to return money from Aliexpress through Chargezbek Aliexpress?

- Payment of purchases on Aliexpress, the better to pay for Aliexpress

- Why can't I pay the world map to Aliexpress? Step-by-step instructions for payment by the world map

- Deliver to Aliexpress, how to order delivery to Aliexpress

- What can not be ordered to aliexpress in order not to disturb the law for which it will be punished

- Aliexpress Optical Tools: Telescopes and Binoculars, Magnifying Glasses, Microscopes, Laser Levels, Laser Rangers, Cornelters, Spectrometers, Optical Glass

- Street lighting on Aliexpress, LED spotlights, LED garland, wall lamps, floor lamp

- Antminer, Antminer Models, Mining Equipment with Aliexpress

- Prototyping fee with Aliexpress

- Aliexpress Accessories Lighting and Lighting: Lights, Switches, Rapad Relays with Aliexpress

- Aliexpress Electronics, Office Electronics, Network Equipment for Aliexpress

- K-Line USB Adapter Aliexpress

- Endoscope with Aliexpress how to buy an endoscope

- How to sell to aliexpress

- Not tracked parcel with Aliexpress

- How to register with Aliexpress in Russian. How to find a good seller and brands for Aliexpress

- Halyava on Aliexpress

- How to return the goods to aliexpress

- When on Aliexpress Sales

- How to contact by the seller for aliexpress

- Sites, Aliexpress Analogs, Information Overview

- Fast delivery to Aliexpress

- What does 1pice mean to aliexpress

- Return money for Aliexpress how to return money from Aliexpress

- Where is the parcel with Aliexpress

- How to sell to Aliexpress from Russia

- How to extend the buyer's defense to Aliexpress

- How to buy a satellite antenna with aliexpress

- Delivery types with Aliexpress

- Best Products for Aliexpress 2016

- How to make money on aliexpress

- Personal Cabinet for Aliexpress in Russian, Aliexpress Entrance to your personal account

- Why can't I go to Aliexpress

- How to pay for goods with Aliexpress, step-by-step instructions

- How to remove an account on aliexpress

- How to order a soldering iron on Aliexpress

- How to buy a USB-Wi-Fi adapter with Aliexpress

- Aliexpress tax 2016 Belarus

Comments